Collision repair safety protocols are crucial for protecting technicians, minimizing risks, and enhancing efficiency in auto body shops. Strict adherence includes mandatory training, PPE use, adherence to industry standards, regular reviews, and implementation of modern tools, fostering a safe work environment that improves productivity, reduces errors, increases revenue, and satisfies customers, ultimately setting businesses apart in the market.

In the fast-paced world of collision repair, prioritizing safety and productivity goes hand in hand. Effective collision repair safety protocols are more than just regulations; they’re a cornerstone of efficient workshops, ensuring the well-being of workers and the quality of repairs. This article delves into the intricate relationship between these safety measures and increased productivity, exploring strategies that can transform your workshop into a safer, more productive environment through strict adherence to best practices.

- Understanding Collision Repair Safety Protocols

- Productivity Gains Through Strict Adherence

- Best Practices for Enhancing Workshop Safety

Understanding Collision Repair Safety Protocols

Collision repair safety protocols are essential practices designed to ensure the well-being of technicians and minimize risks during vehicle repair processes. These protocols encompass a comprehensive set of guidelines, including proper training, use of personal protective equipment (PPE), and adherence to strict safety standards. By implementing these measures, collision repair facilities create a safer working environment, reducing the likelihood of accidents and injuries.

Understanding these safety protocols is crucial for all involved in the car repair services industry. Technicians must be adept at following instructions, utilizing safety gear such as gloves, goggles, and masks, and staying vigilant to potential hazards. Moreover, regular reviews and updates of these protocols are necessary to keep up with advancements in technology and best practices in vehicle damage repair, thereby fostering a culture of safety within collision repair shops and promoting the overall efficiency of the process.

Productivity Gains Through Strict Adherence

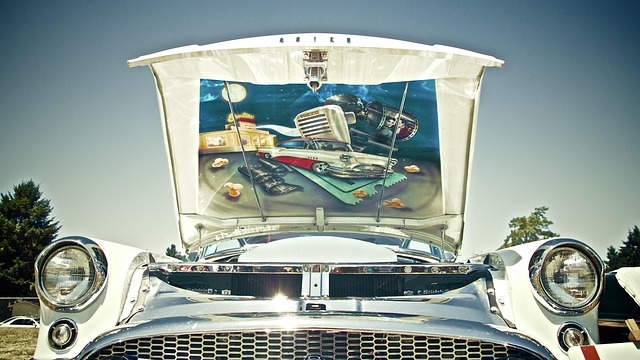

Strict adherence to collision repair safety protocols isn’t just about compliance; it’s a powerful driver of productivity gains for auto body shops. When staff are trained and consistent in following safety procedures, it streamlines workflows and reduces errors. This means faster turnaround times for car body repair and car scratch repair services, as well as fewer repeat jobs due to mistakes, both of which directly translate into increased efficiency and revenue for the shop.

Imagine a well-oiled machine where every employee knows their role and follows standardized protocols – this is the environment that safety adherence fosters. It eliminates unnecessary delays, promotes effective use of resources, and ensures consistent quality in auto repair near me services. The result? A happier customer base and a thriving business that can compete effectively in the market, offering not just reliable collision repair but also safe and efficient solutions for all their automotive needs.

Best Practices for Enhancing Workshop Safety

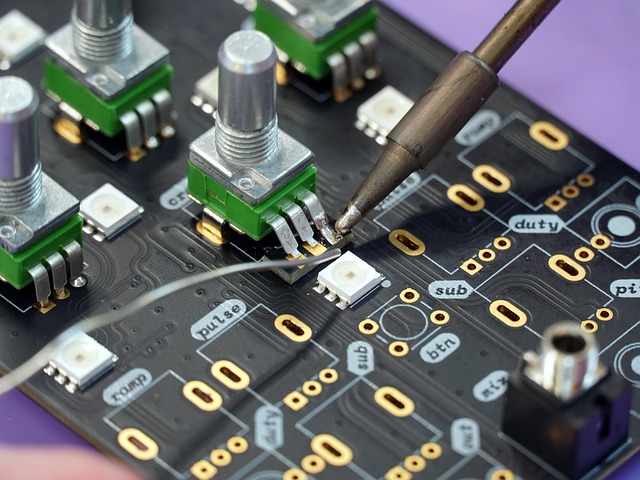

In collision repair workshops, implementing best practices for enhancing workshop safety is paramount to ensure a secure and efficient working environment. This includes adhering to established collision repair safety protocols, such as proper ventilation to mitigate the risk of hazardous fumes from car paint repair and scratch repair processes. Regular training sessions for employees on safety measures, personal protective equipment (PPE), and emergency response procedures are essential. Workshops should be designed with clear pathways and organized workstations to minimize tripping hazards and facilitate smooth workflow, reducing potential collisions among personnel.

Additionally, utilizing modern tools and technologies can significantly improve safety. For instance, automated systems for car bodywork services can decrease manual labor risks and enhance precision. Regular inspections of equipment and facilities are crucial to identify and rectify potential dangers promptly. Foster a culture of open communication where employees feel comfortable reporting safety concerns or near-miss incidents. By incorporating these practices, collision repair businesses can create a safer atmosphere, leading to higher productivity while upholding quality standards in car paint repair services.

Collision repair safety protocols, when strictly adhered to, can significantly enhance workshop productivity while ensuring the well-being of personnel. By implementing best practices and fostering a culture of safety, auto body shops can streamline operations, reduce errors, and create a more efficient environment. These protocols are not merely regulatory requirements but essential tools for optimizing both safety and productivity in collision repair.